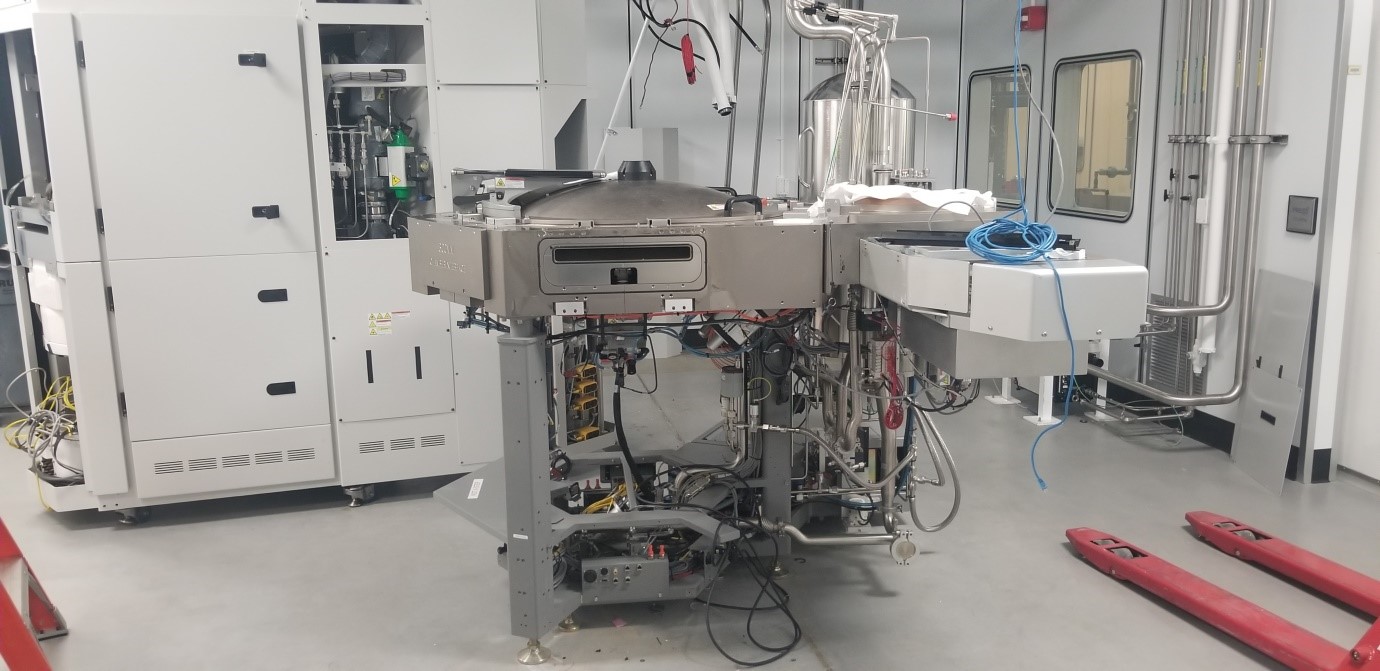

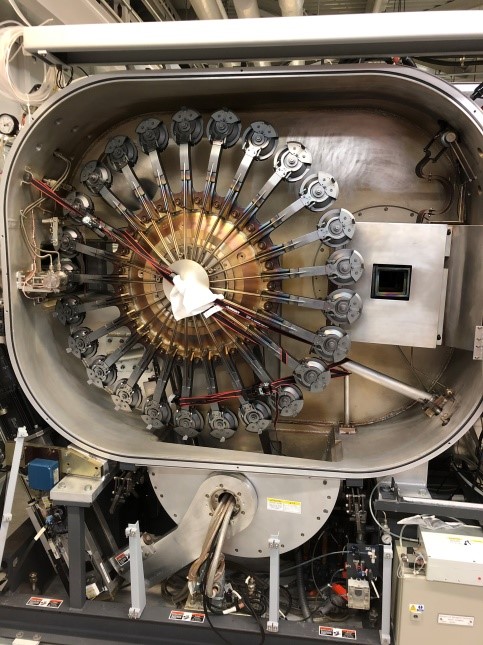

VESCO has over 15 years of experience decommissioning and de installing delicate semiconductor tools and equipment. Among those tools are MBEs, MOCVDs, and PVDs, just to name a few.

Every tool is unique and requires careful planning and proper procedures to decommission and de install. There is no margin for error when it comes to safety. Many of these tools can contain a variety of hazardous materials, which is why safety is the number one priority when planning decommissioning and de installation procedures.

We have decommissioned and de installed single tools, and we have also taken entire production facilities offline with more than 100 tools being decommissioned. We have worked with clients worldwide.

Our team of professionals has the expertise and range to take on projects of all sizes.

How a tool is disassembled plays a crucial role in preserving its value and ensuring that only the proper components are secured, disassembled, or removed. Proper planning is essential when reassembling or reinstalling the tool elsewhere.

Most complex semiconductor tools are modular in design and cannot be moved as a single piece. Removing the outer enclosure first will reveal which modules can be taken out and which should remain. It is imperative to work closely with facility management to determine the safest and most efficient exit strategy for the tool. Measuring the tool’s dimensions against exit way dimensions and corners helps avoid unexpected delays.

We provide the highest quality service to all our clients. Our estimates are fair and reasonable, and we guarantee the most cost-effective prices with the quickest turnaround times. References are always available upon request, and our portfolio of clients speaks for itself.