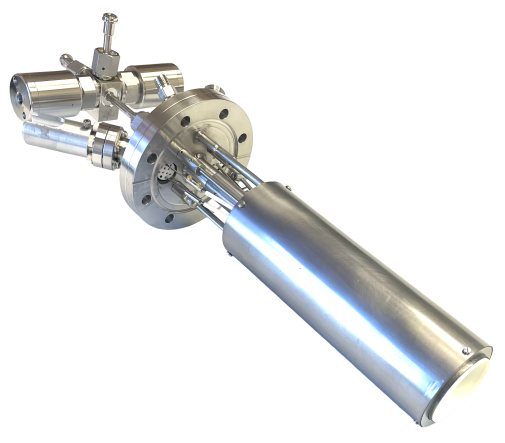

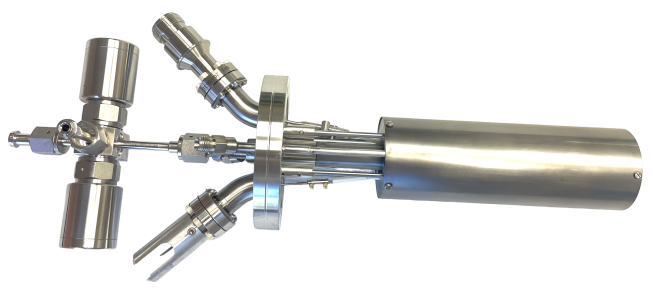

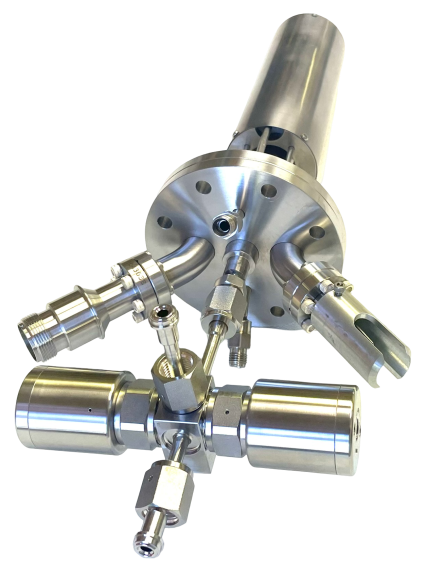

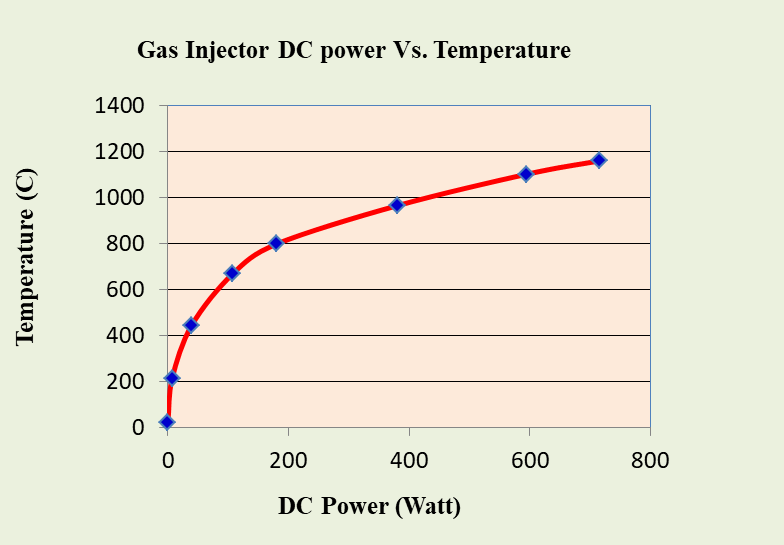

Gas injectors are used in gas-source MBE and CBE systems to generate a stable molecular beam with uniform intensity. They also use to mix different gases, of the same group, to achieve high degree of material composition uniformity. VESCO-NM gas injectors are adapted for most gas-source MBE and CBE systems. Our gas injectors have independent 1/4 inch VCR male gas inlet and are equipped with high-temperature (200°C max) normally-closed pneumatic actuators. Cracking zone contains 0.25” OD inner tube and 0.75” OD outer tube and PBN cone to achieve high uniformity on the substrate. The single heater can reach up to 1250o C There are two types of gas injectors: Low temperature (< 100°C) for on- substrate cracking and high temperature (> 600°C) to decompose the species before impinging on the substrate. Normally the complete gas injector source package consists of:

| Mounting Flange | 4.5” |

|---|---|

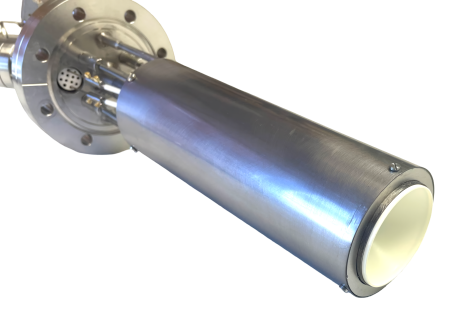

| In-Vacuum Length | 9.7” |

| In-Vacuum Tube Diameter | 2.4” |

| Water Cooling Coil OD | 0.1875” |

| Front Cone | PBN |

| Conductance Tube | Tantalum |

| Bake Out Temperature | 200 °C |

| Maximum Gas Inlet | 1 |

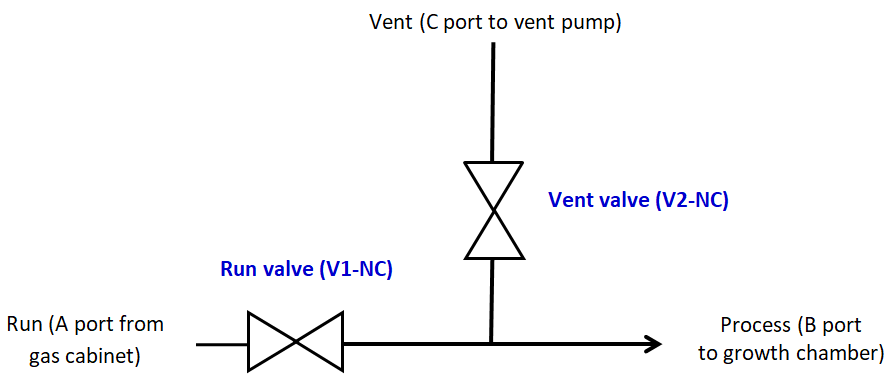

| Number of Run Actuators | 1 |

| Number of Vent Actuators | 1 |

| Gas Inlet | ¼ inch VCR |

| Typical Operating Temperature | 950 °C |

| Maximum Operating Temperature | 1200 °C |

| Maximum Outgassing Temperature | 1250 °C |

| Heater | Single tantalum filament |

| Thermocouple | Type C |

| Power Supply | Single power supply (800–1000 Watts) |

| Temperature Controller | 1 |