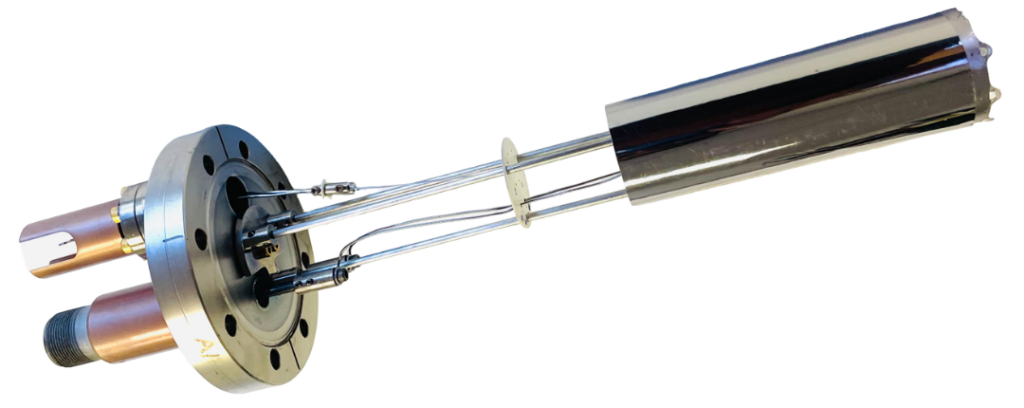

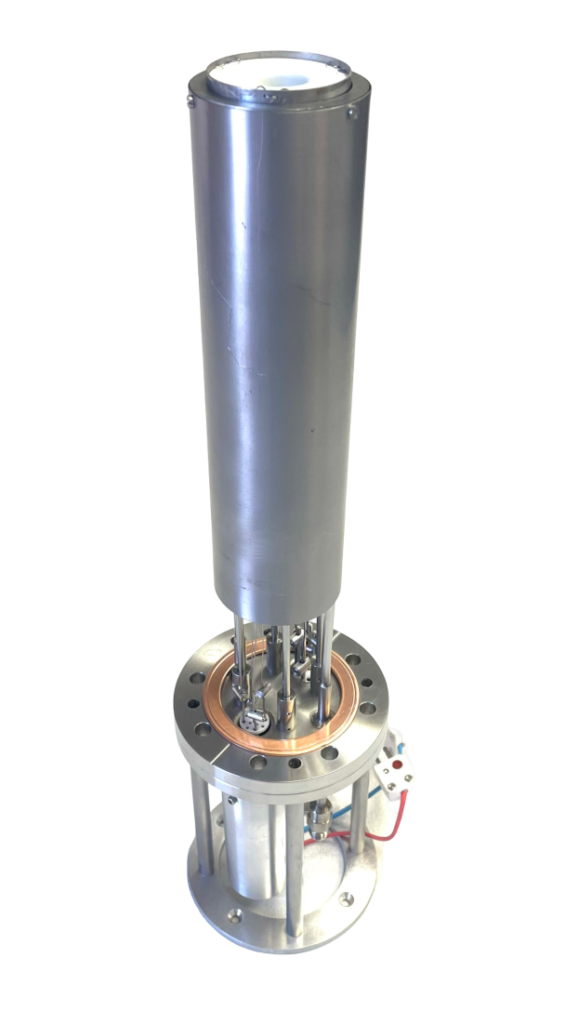

EFFUSION CELLS are the most vital components in an MBE system. They have considerable impact on the quality of the grown layer, such as surface morphology, thickness and composition uniformity, and film purity. System efficiency is greatly affected by effusion cells, regarding throughput and machine run time. VESCO-NM manufactures different sizes of effusion cells for various sources and purposes from low-temperature to high-temperature applications. Our effusion cells are compatible with different MBE systems and can be installed in various orientations in MBE systems. VESCO-NM effusion cells are also easy to rebuild and to maintain.

| Mounting Flange | 2.75” CF flange (other upon request) |

|---|---|

| Heater | Tantalum wire 0.040” OD |

| Temperature Range | 100 °C – 1000 °C |

| Temperature Stability | ± 0.1 °C |

| Crucible Type | PBN, Al₂O₃, Quartz (other upon request) |

| Crucibles Volume | 2–200 cc (as required) |

| Evaporated Materials | High vapor pressure and organic materials |

| Thermocouple Type | Type K |

| Outgassing Temperature | 1100 °C |

| In-Vacuum Dimensions | 12” long, 1.4” OD (other on request) |

| Bakeout Temperature | 250 °C |

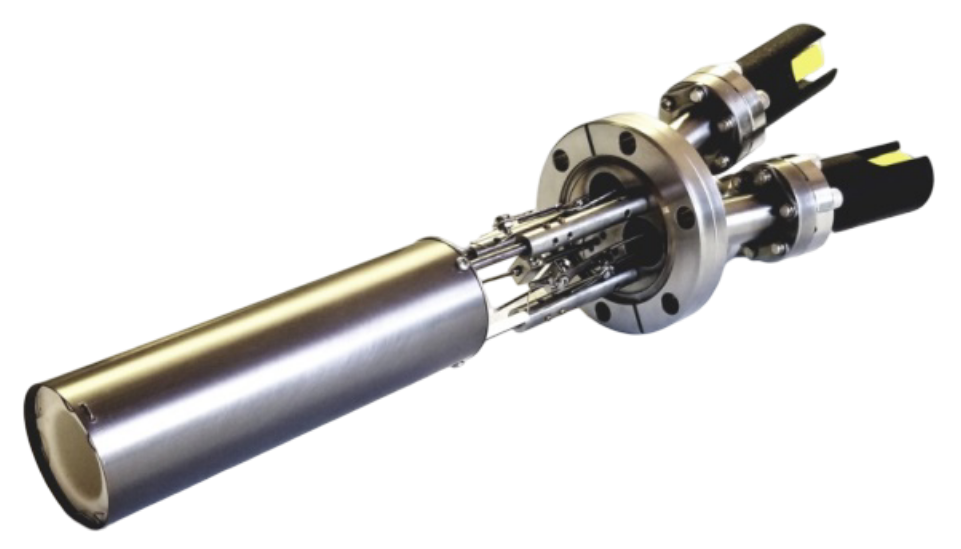

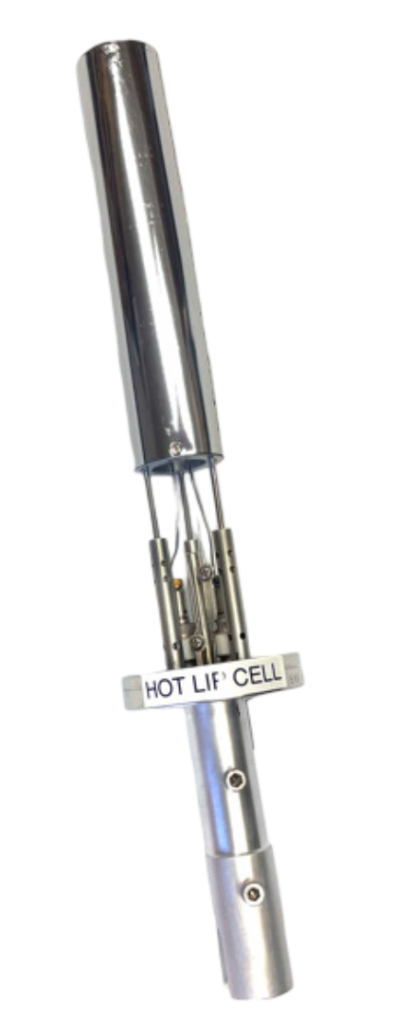

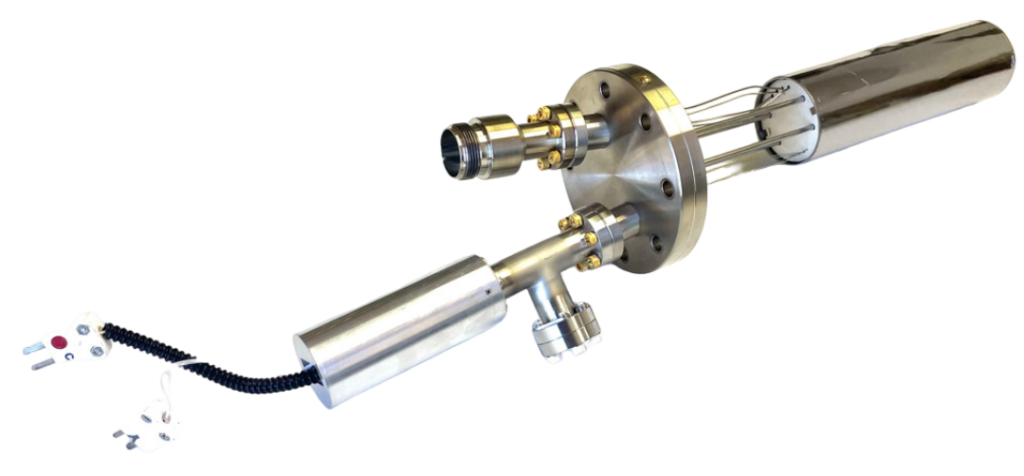

| Mounting Flange | 2.75” and 4.5” (other upon request) |

|---|---|

| In-Vacuum Dimensions | 12” long and 2.4” OD (other upon request) |

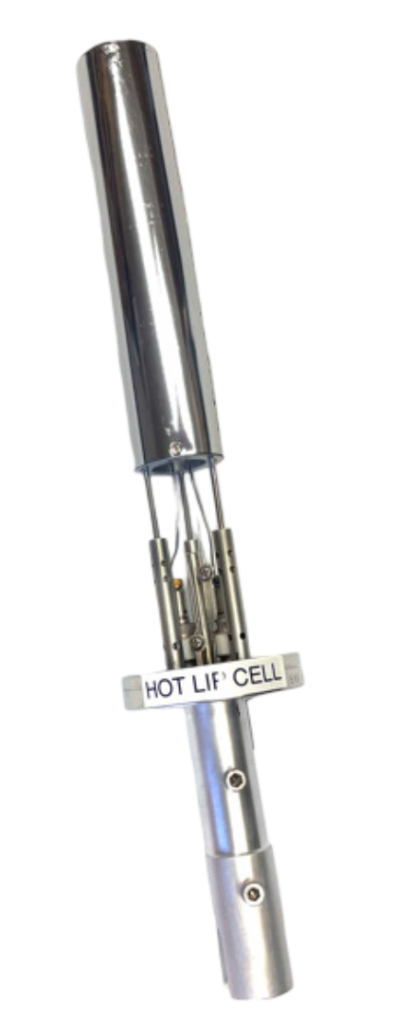

| Heater Types | Ta wire, 0.04” OD, single, hot lip, cold lip, and dual heater |

| Thermocouple | Type C |

| Operating Temperature | 500–1300 °C |

| Outgassing Temperature | 1450 °C |

| Bakeout Temperature | 250 °C |

| Cooling Option | Integrated water cooling coil |

| Crucible Size | 5–400 cc |

| Option | Integrated shutter |

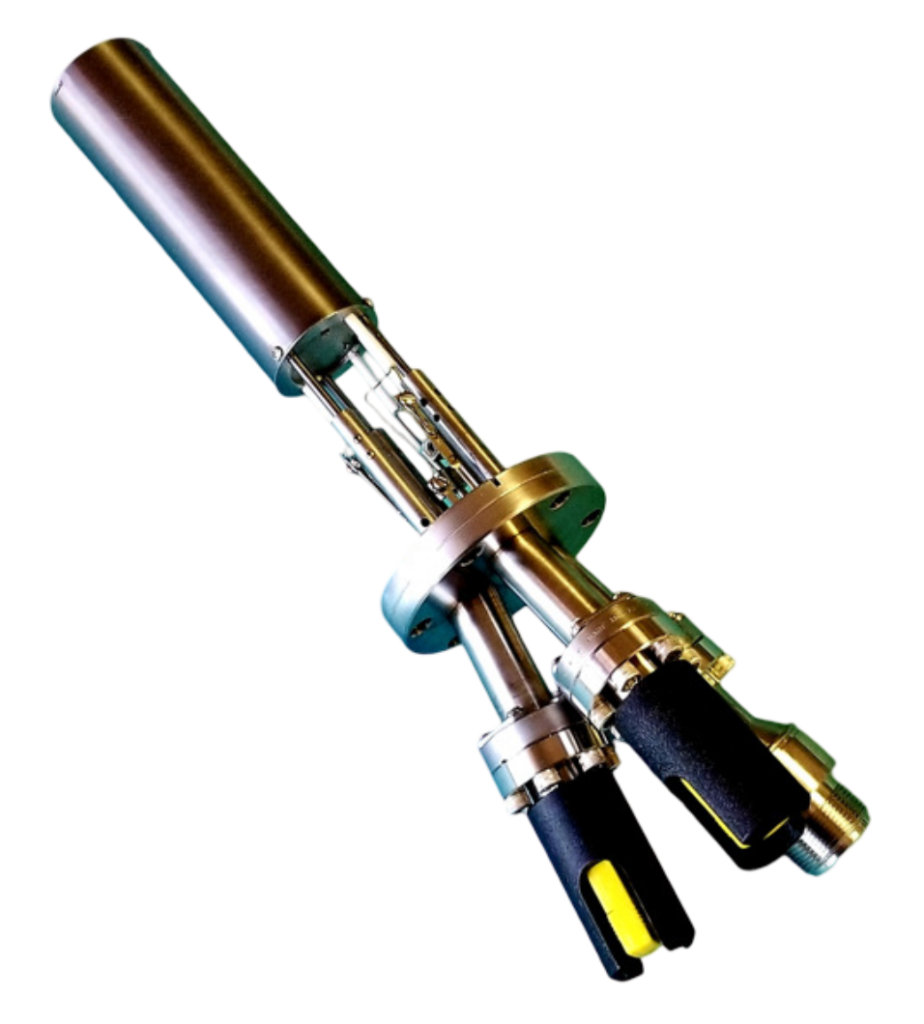

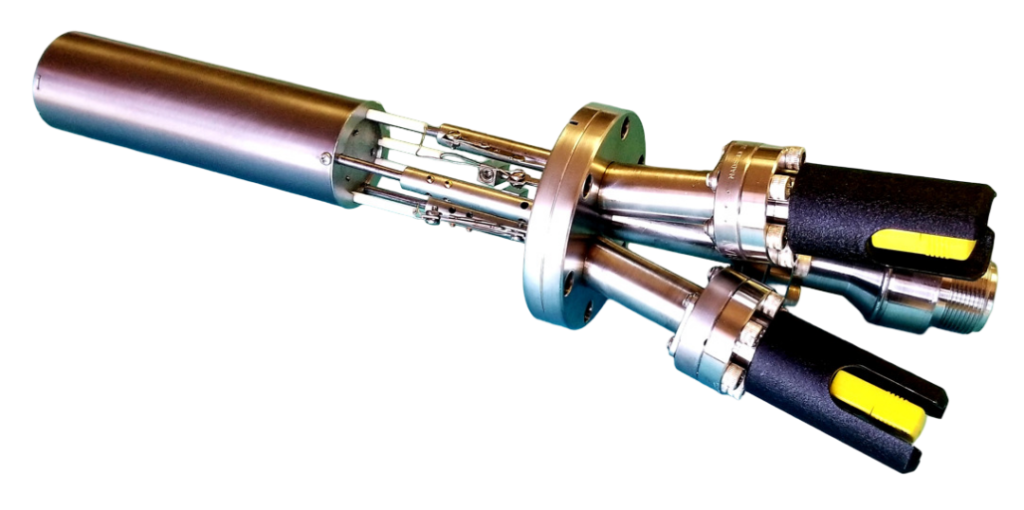

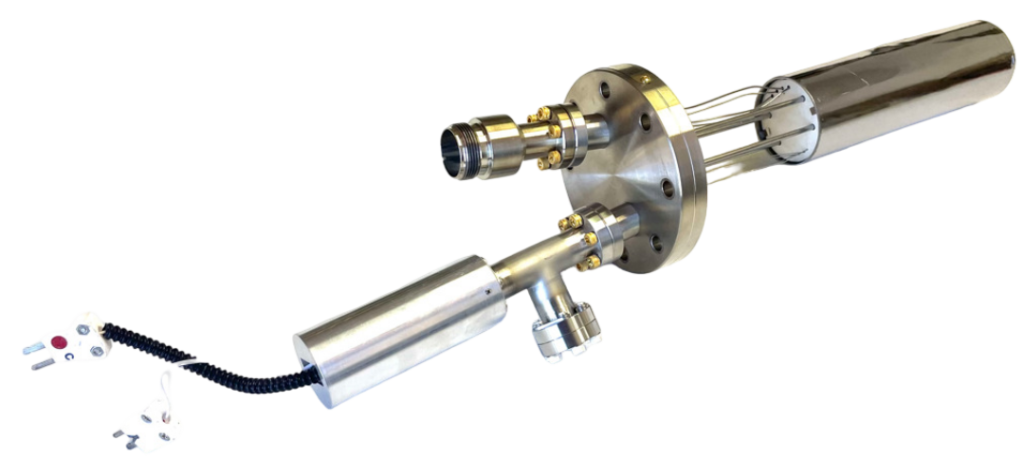

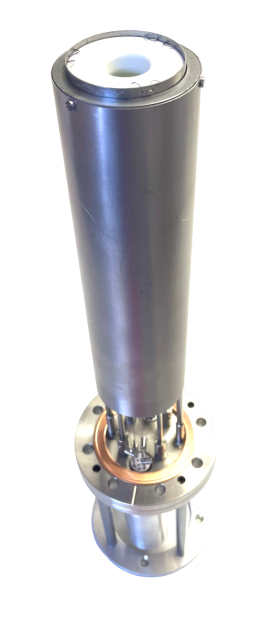

VESCO-NM doping effusion cells are designed for evaporation or sublimation of elemental and compound materials, such as Si, Be, and GaTe, in the temperature range from 200°C to 1350°C. Effusion cells heaters are fabricated using 0.040” OD thick tantalum wire with PBN supporting rings; therefore they have excellent temperature uniformity and high reliability. Effusion cells with conical shaped crucibles and different materials (PBN, PG, and Al2 O3) are available. We also supply dual dopant cluster sources if two or more dopant materials are in need.

| Mounting Flange | 2.75” and 4.5” (other upon request) |

|---|---|

| Crucible Size | 2–25 cc |

| In-Vacuum Dimensions | 12” long and 2.4” OD (other upon request) |

| Heater Types | Ta wire, 0.04” OD, single, hot lip, cold lip, and dual heater |

| Thermocouple | Type C |

| Operating Temperature | 200–1340 °C |

| Outgassing Temperature | 1450 °C |

| Bakeout Temperature | 250 °C |

| Options | Integrated water cooling, standoffs, shutter |

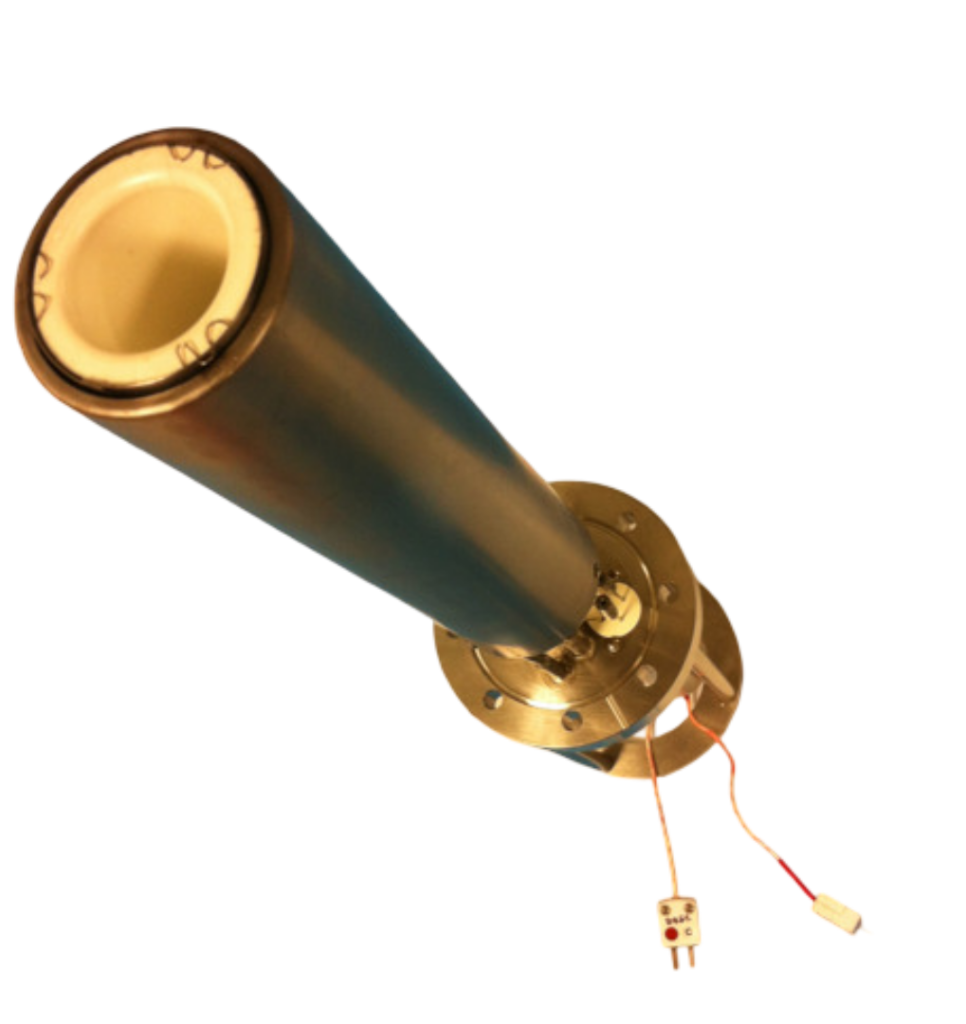

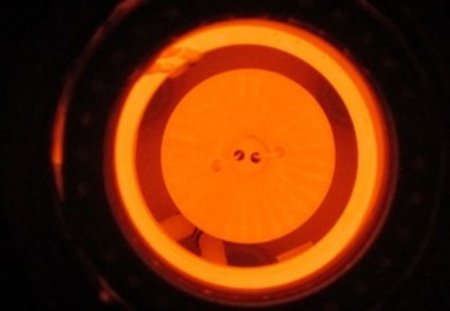

High-temperature effusion cells are designed for the evaporation or sublimation of low vapor-pressure materials such as Fe, Cr, Ni, Co, Au, Ge, etc., in the temperature range of 1500 °C–2000 °C. Typical applications include the growth of magnetic or oxide thin films and surface analysis deposition. The heater element of these cells is fabricated using self-supporting thick tungsten coils or wires. Tungsten or tantalum shields are used to confine the heater inside the crucible. No ceramic or PBN insulation parts are directly used inside the hot zone. Different crucible materials are available, such as Al₂O₃, BeO, Ta, and W. The maximum operating temperature of the cell is limited by the crucible material, e.g., up to 1550 °C for PBN and 1800 °C for PG. Reactions between crucible materials and evaporation materials are another factor that can reduce the maximum allowable temperature.