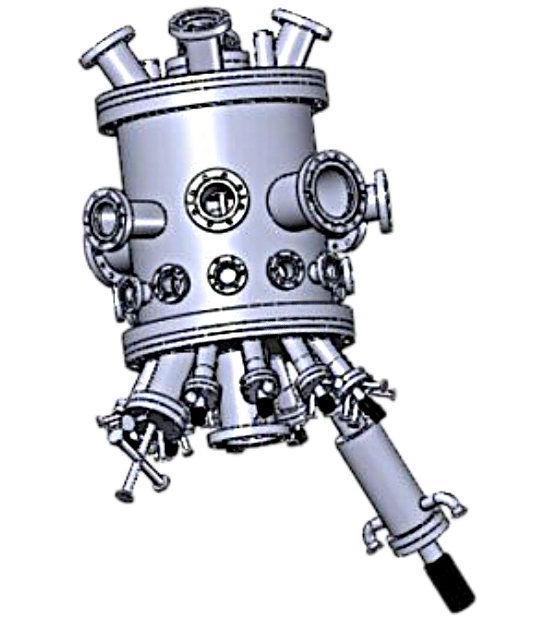

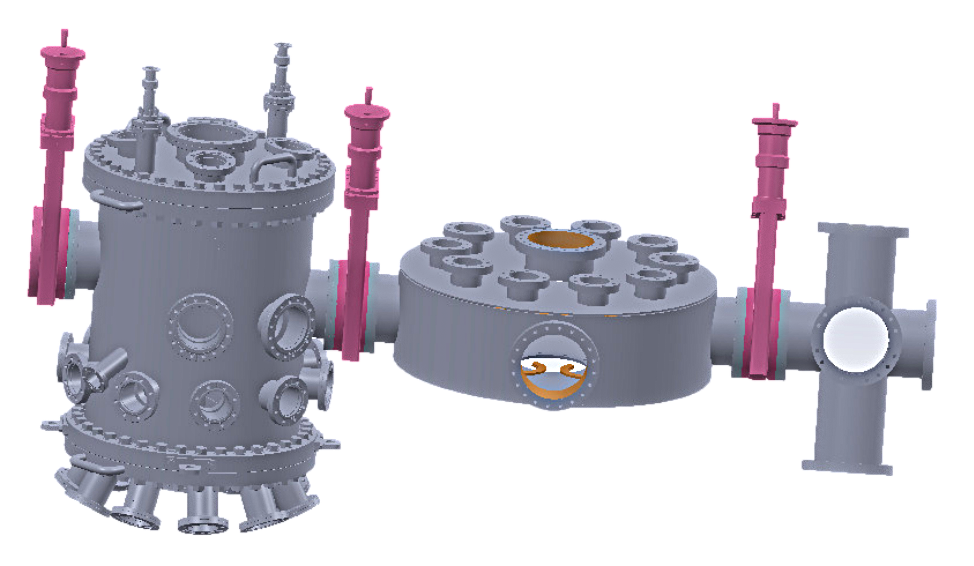

| Growth Chamber Size | 22” OD, 24” height |

|---|---|

| Buffer Chamber Size | 28” OD, 10” height |

| Load Lock Chamber Size | 6-way 8” cross |

| Wafer Cassette Size | Two cassettes, 8 sample holder each |

| Buffer Chamber Capacity | 8 sample holders 36 degrees apart |

| Substrate Size | up to 3 inch |

| System Pumping Stations |

Growth chamber: Cryo, ion, and TS pumps Buffer chamber: Ion and TS pumps Load lock: turbo and scroll pumps |

| Cooling Shroud | LN2 or other cooling liquid |

| Substrate Heater Temperature | Up to 1200 °C |

| Bakeout Temperature | Up to 200 °C |

| Sources Port Sizes | 4.5” CF flange |

| Types of Sources | Effusion cells, valved crackers, RF plasma sources, e-beam sources, sublimation sources, and gas injector sources |

| Shutters | Magnetically coupled liner shutters |

| In-situ Monitoring | Ion gauge, QCM, pyrometer, RHEED, QMA |

| Sample Transfer | Robot transfer arm with azimuth and z travels |

| Service | System installation and acceptance testing |

| Training | By MBE experts |